Product Details

- Description

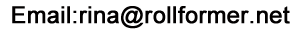

It is a standard machine to produce C and Z purlin. The thickness will be 1-3mm, and size will from 100 to 300mm. As a standard machine, there will have two kinds of holes in CZ purlin. I will quote you a standard machine, if you have any special requirement, i will quote you again.

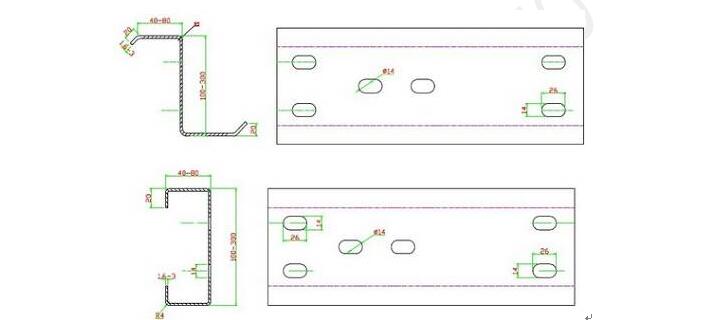

- Working flow:

Uncoiler—Feeding—Roll forming—Hydraulic cutting—output table

- Main Specification

- 5T manual decoiler

1) Capacity: 5 ton

2) Loading width: MAX 300mm

3) Valid expanding range for coil inner diameter: 450-550mm

- Main roll forming system with cutting

- Main motor power: 15kw

- Feeding and leveling power: 4KW

- Hydraulic power:5.5KW

- Hydraulic pressure: 20Mpa

- Punching: Hydraulic pre-punching before forming,

- Punching mould:Cr12mov

- Cutting: Hydraulic pre-cutting before forming, Auto cutting when reach the

- set length.

- Cutting blade: Cr12mov

- Cutting tolerance: +/- 1.5mm

- Drive: Chain

- Roller material: Gcr15 steel and quench treatment hardness 55-58, chrome

coated 0.05mm

- Leveling rollers: 7rollers(three upper and four lower)

- Roll station: 16groups

- Raw material: 1.0-3.0mm

- Valid width after formed: 100mm-300mm

- Motor for width adjusting: 4.5KW(1.5KW*3)

- Working speed: 10m--15m/min(Exclude cutting time)

- Length Tolerance: ±1.5mm

- Weight of machine: about 14ton

- Size of machine: About 11000×1800×1800mm L x W x H

- Color of machine: depend on customer

- Coder: Omron

- Control: PLC 380V 50HZ

- Computer operating panel: touching screen