Material requirement:

1 Galvalume, ASTM A 792, structural grade A37,AZM-150 coating, AFP,Regular spangle, coil weight: max 5 mt, coil ID 508 mm

2 Prepainted galvalume with protection film base matal, galnized, ASTM653 6 60 structural grade A37. Paint: top 5+20 microns RMP/Back 5 microns Epoxy Coil weight: max 5mt, coil ID:508mm.

3 Galvanized, ASTM 653 G 90 structural grade A37 REGULAR SPANGLE, COIL WEIGHT: MAX 5MT, COIL id508MM

4 Thickness: 0.3-0.8MM

5 Width:1219mm(48 inch)

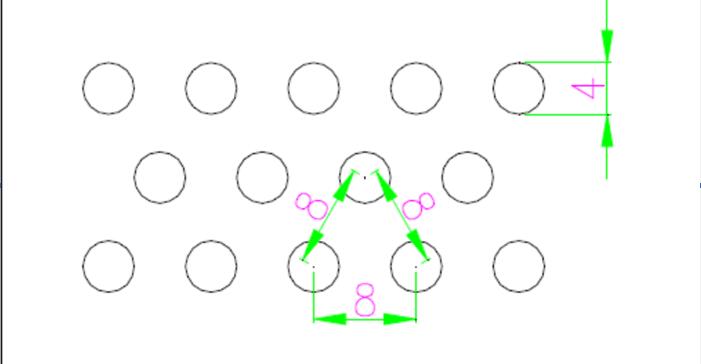

Holes pattern:

1 Technical process:

5 tons hydraulic Decoiling –Flattener–pre punching-flattener and cut to length-Run out table-5 tons hydraulic recoiling

In this working flow, if you need the cut to length the punched sheet, you can use the run out table. If you do not need to cut to length, you can move away the run out table,and use the re-coiler system

| No | Name | Quantity |

| 1 | 5 tons hydraulic de-coiler | 1unit |

| 2 | Straightener | 1unit |

| 3 | Punching machine | 1unit |

| 4 | Straightener | 1unit |

| 5 | Cut to length | 1unit |

| 6 | Receiving table | 1unit |

| 7 | Recoiler system | 2 units |

Feeding Material specifications

| Thickness | mm | 0.3-0.8 | |

| width | mm | 1219 | |

| Coil I.D | mm | Φ508 | |

| Coil weight | Ton | 5 ton |

4 Output sheet and coil specification

| Embossed sheet | Thickness | mm | 0.3-0.8 |

| Length | mm | 4000 | |

| Embossed Big coil | Coil I.D | mm | Φ508 |

| Coil weight | Ton | 5 | |

| Embossed Small coil | Coil I.D | mm | 150 |

| Coil weight | Ton | 0.4 |

5.1. 5 ton hydraulic decoiler

| 1 Coil inner diameter: 450-550mm

2 Max coil out diameter:1300 -1600 mm 3 Max coil width: 1250mm 6 Automatically feeding 7 Hydraulic, inner tight 8 Hydraulic power : 3 kw Drive power:3kw 9 Size:2.7*1.3*1.8m(L*W*H) 10 220V,3 Phrase,50HZ |

Punching system and cutting to length

Power: 220V,3 Phrase,50HZ

- different punching pattern can be made by changing the punching molds.

2.The machine is welded by steel plate. Equipped with system of double-roller automatic feeding, compulsory and automatic lubricating, low pressure protection for stopping and pneumatic clutch, this machine can meet various requirements from customers.

3.The machine can be used for producing round hole sheet, wind and dust suppression mesh, square hole mesh, decoration sheet, polygon mesh and other strange shape of mesh.

4.The material of sheet can be iron, steel, stainless steel, aluminum, tin, copper and other material.

5.The type of 250T machine is automatic and pneumatic and it is very during and stable.

6.It is easy to use, usually 2 men are enough to operate 4 or 6 sets of this type of machine.

6.According to the sheet the customer produce, some other small equipment is need, such as coiler, decoiler and leveling machine. Customers can choose to buy it or make it by themselves.